SOLVEST exceeding customer's requirement

Four types of multiple lineup

High customization for your needs

Integrated production and quality control from development to processing of special lubricant.

Solid lubricants are lubricating solids and are particularly effective for lubrication in high load conditions or harsh areas beyond the lubrication area of oil. It has characteristics that reduce friction and wear of the lubrication part, prevent a long service life and damage to parts.

Solid lubricants are lubricating solids and are particularly effective for lubrication in high load conditions or harsh areas beyond the lubrication area of oil. It has characteristics that reduce friction and wear of the lubrication part, prevent a long service life and damage to parts.

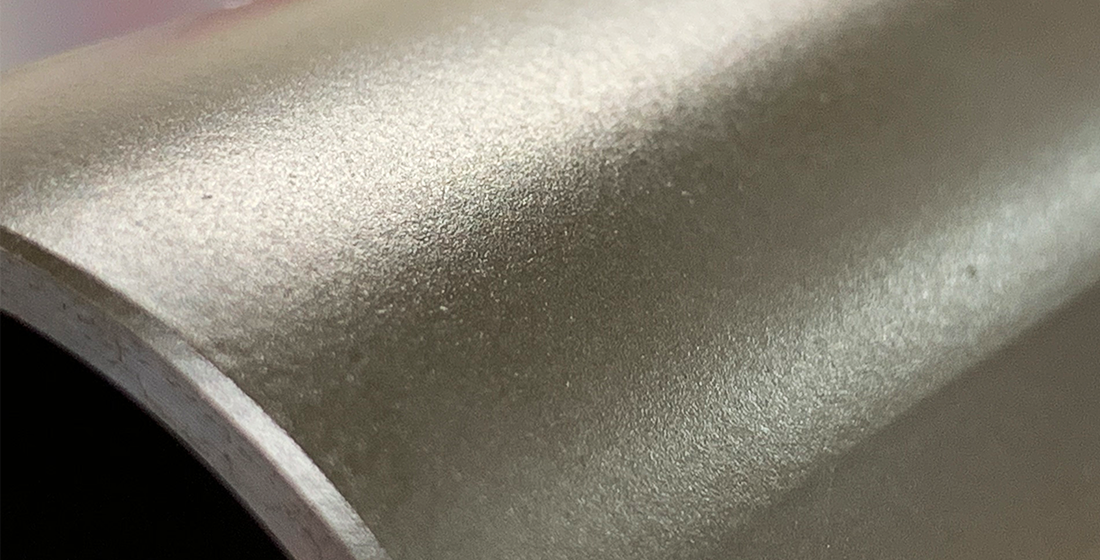

It is a paint type lubricant product in which a solid lubricant and various binders are dispersed in a solvent.

By coating in the same way as paint, dry lubricating film is obtained.