-

Dry coat

300(+)

-

Dry coat

SOLVEST 300(+)

The solid lubricant is compounded to a high concentration with a quick-drying lubricating film, and the initial fit of various industrial machines and machine parts. Accuracy of cold forging, drawing of metal processing, extrusion of aluminum. It can be widely used under severe conditions such as extension of tool life, prevention of screw and pin seizure and galling, and vacuum.

Lubricant component

Molybdenum disulfide

Graphite

Base binder

Inorganic resin

Curing conditions

Cold curing

Temperature range(°C)

-200 to 500

Employed industry

Automobile

The solid lubricant is compounded to a high concentration with a quick-drying lubricating film, and the initial fit of various industrial machines and machine parts. Accuracy of cold forging, drawing of metal processing, extrusion of aluminum. It can be widely used under severe conditions such as extension of tool life, prevention of screw and pin seizure and galling, and vacuum.

-

Dry coat

305(+)

-

Dry coat

SOLVEST 305(+)

Excellent for high-speed, low-load applications. Used for rust prevention, lubrication, seat belt parts, plungers, etc.

Curing conditions

200 ° C x 30 minutes

Temperature range(°C)

-200 to 300

Employed industry

Automobile

Industrial equipment

Excellent for high-speed, low-load applications. Used for rust prevention, lubrication, seat belt parts, plungers, etc.

-

Dry coat

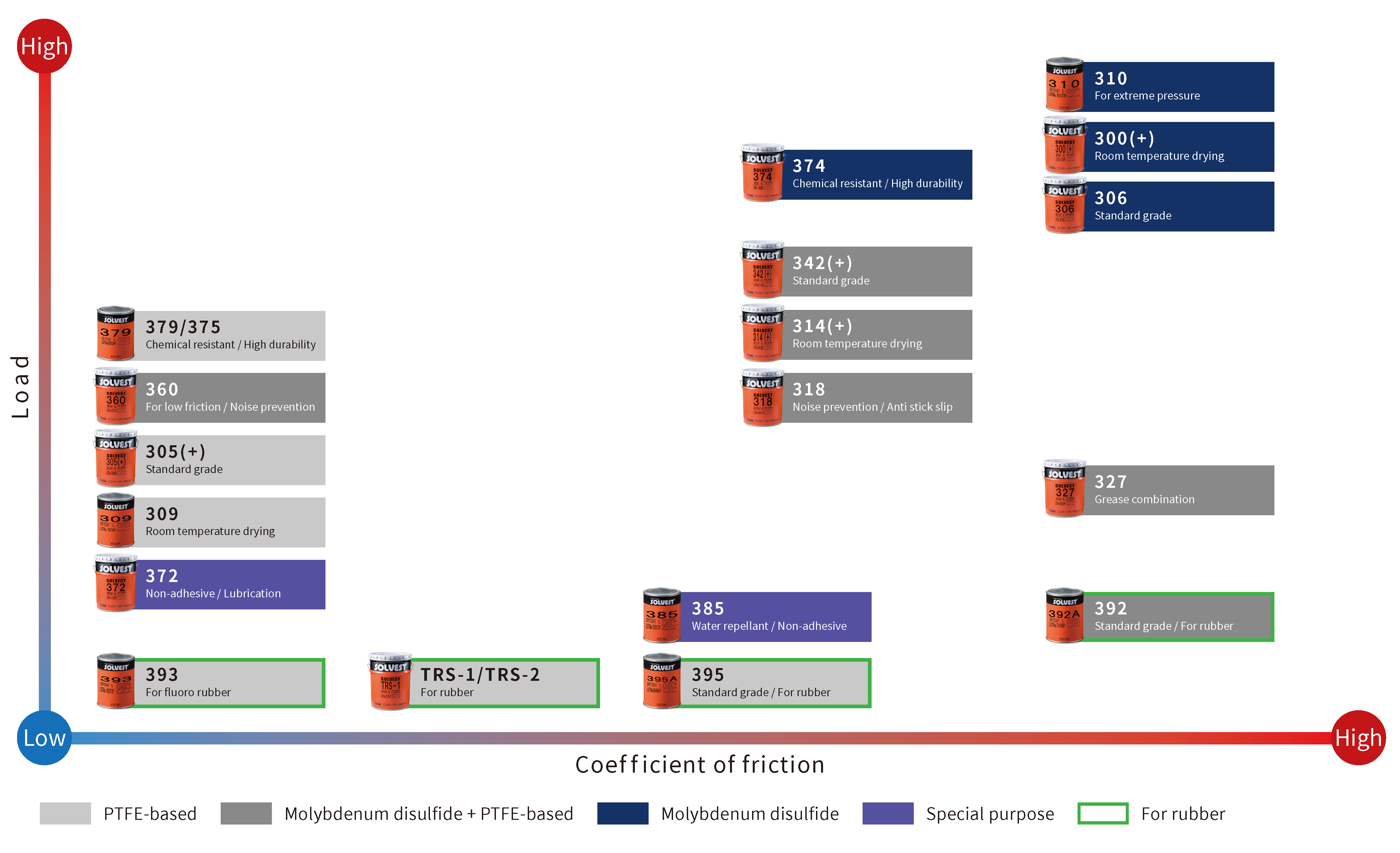

306

Excellent for high-load applications. Initial familiarity and lifetime lubrication of machines and parts.

-

Dry coat

310

A solid lubricant is compounded to a high concentration, and a special solid lubricant excellent in extreme pressure properties is compounded. Lubricant for cold forging.

-

Dry coat

314(+)

Room temperature drying type of 342 (+).

-

Dry coat

318

-

Dry coat

SOLVEST 318

Excellent noise and stick-slip prevention under dry and grease conditions. Spring noise, cracks, breakage, rust prevention.

Lubricant component

Molybdenum disulfide

PTFE

Curing conditions

215 ° C x 40 minutes

Temperature range(°C)

-200 to 300

Employed industry

Automobile

Excellent noise and stick-slip prevention under dry and grease conditions. Spring noise, cracks, breakage, rust prevention.

-

Dry coat

327

Grease combination type of 342 (+).

-

Dry coat

342(+)

-

Dry coat

SOLVEST 342(+)

Standard product applicable from low load to high load. The most abundant use cases such as anti-corrosion, lubrication, door lock, latch, plunger, valve, screw and so on.

Lubricant component

Molybdenum disulfide

PTFE

Curing conditions

200 ° C x 30 minutes

Temperature range(°C)

-200 to 300

Employed industry

Automobile

Industrial equipment

Building materials

Standard product applicable from low load to high load. The most abundant use cases such as anti-corrosion, lubrication, door lock, latch, plunger, valve, screw and so on.

-

Dry coat

360

Formulated with special solid lubricant, excellent noise and stick-slip prevention under grease combined condition. Used for automotive interior mechanism parts.

-

Dry coat

372

It is excellent in non-stickiness by blending PTFE and special additives. For preventing adhesive tape sticking such as tape cutter blade.

-

Dry coat

374

-

Dry coat

SOLVEST 374

It is excellent in high load applications by combining polyamide imide resin and molybdenum disulfide which are excellent in abrasion resistance and chemical resistance.Heat resistant, chemical resistant, long term lubrication application.

Lubricant component

Molybdenum disulfide

Graphite

Base binder

Polyamide imide resin

Curing conditions

230 ° C x 30 minutes

Temperature range(°C)

-200 to 300

Employed industry

Automobile

It is excellent in high load applications by combining polyamide imide resin and molybdenum disulfide which are excellent in abrasion resistance and chemical resistance.Heat resistant, chemical resistant, long term lubrication application.

-

Dry coat

379

-

Dry coat

SOLVEST 379

It is excellent in high speed and low load applications by blending polyamideimide resin and PTFE, which are excellent in abrasion resistance and chemical resistance. Heat resistant, chemical resistant, long term lubrication application.

Base binder

Polyamide imide resin

Curing conditions

230 ° C x 30 minutes

Temperature range(°C)

-200 to 300

Employed industry

Automobile

It is excellent in high speed and low load applications by blending polyamideimide resin and PTFE, which are excellent in abrasion resistance and chemical resistance. Heat resistant, chemical resistant, long term lubrication application.

-

Dry coat

385

Formulated with a special silicone resin that is excellent in water repellency and non-stickiness. It is excellent in the water repellency of metal and resin, and the releasability of the adhesive.

-

Dry coat

392

A two-component type for rubber and plastic containing molybdenum disulfide and PTFE.Rubber noise prevention, friction reduction, long-term lubrication applications.

-

Dry coat

393

1 part type for fluoro rubber, for sticking prevention.